Ntawv Hlau

Ntawv Hlau Fabrication

Peb kev cai daim ntawv hlau cov kev pabcuam pub rau tus nqi-thiab ua tau raws li koj cov kev xav tau ntawm kev tsim khoom. Peb muaj qhov nrawm nrawm, lub xeev ntawm cov khoom siv hlau tsim cov khoom siv uas zoo tshaj plaws rau kev tsim cov kav ntev, qhov kawg siv cov hlau nrog qhov rov ua dua, qis-rau-siab thiab qhov siab sib xyaw tsim tawm uas yog tsim rau koj cov kev qhia tshwj xeeb.

Ntawv hlau ua hauj lwm yog txheej txheem ntawm kev ua haujlwm hlau uas tsim cov khoom tshiab los ntawm ntau hom ntawv hlau. Cov txheej txheem cua sov tau siv los ua kom tawv los yog ua kom tawv ncauj ntawm cov hlau los ntawm cua kub lossis cua txias nws kom txog thaum nws mus txog qib uas xav tau ntawm qhov nyuaj, thiab kuj yog li ntawd nws yog nyob rau hauv ib daim ntawv uas ua haujlwm tau. Ntau cov tswv yim tseem ceeb yuav raug siv rau hauv kev kho cua sov, suav nrog kev sib koom ua kom zoo, quenching, nag lossis daus kom muaj zog thiab npau taws.

Npaum Li Cas Cov Ntaub Ntawv Hlau Ua Haujlwm

Muaj 3 ntu tshwm sim hauv cov txheej txheem hlau fabrication, tag nrho cov uas tuaj yeem ua tiav nrog ntau hom kev tsim cov khoom siv.

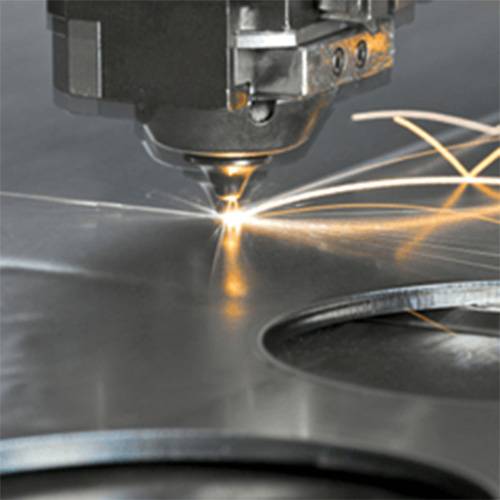

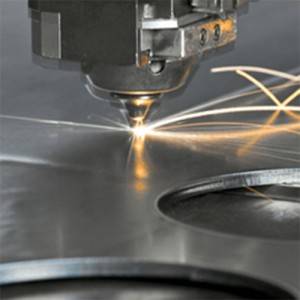

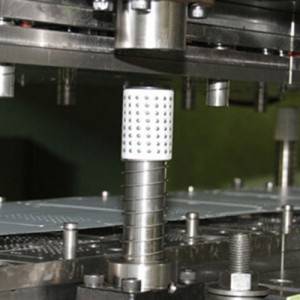

● Tshem tawm cov khoom: Lub sijhawm no, cov haujlwm ua haujlwm nyoos yog txiav rau cov duab uas xav tau. Muaj ntau ntau yam cuab yeej thiab cov txheej txheem machining uas tuaj yeem tshem cov hlau tawm ntawm qhov chaw ua haujlwm.

● Khoom Deformation (txoj kev ua): Cov ntawv hlau me me yog khoov los yog tsim rau hauv cov qauv 3D tsis tshem tawm ib qho khoom siv twg. Muaj ntau ntau cov txheej txheem uas tuaj yeem hloov qhov chaw ua haujlwm.

● Assembling: Cov khoom tiav tuaj yeem sib sau los ntawm ntau cov txheej txheem ua tiav.

● Ntau lub chaw muaj kev pabcuam xov tiav thiab. Cov txheej txheem tiav feem ntau yog tsim nyog ua ntej daim ntawv hlau qhov khoom ntim tau npaj rau hauv kev ua lag luam.

Cov ntawv thov rau Sheet hlau

Cov Ntaub Ntawv Tso Nrog - Cov ntawv hlau muaj ntau txoj hauv kev ua kom zoo rau kev tsim cov khoom lag luam vaj huam sib luag, cov thawv ntawv thiab cov rooj plaub rau ntau yam kev siv. Peb tsim cov ntaub thaiv ntawm txhua tus qauv, suav nrog rackmounts, "U" thiab "L" cov duab, nrog rau cov khoom siv thiab cov chaw ua si.

Chassis - lub chassis peb sib tsoo feem ntau yog siv los ntsuas hluav taws xob hauv tsev, los ntawm cov khoom siv me me mus rau cov cuab yeej ntsuas khoom loj. Txhua lub chassis ua tau rau qhov tseem ceeb kom paub meej qhov qhov sib ncag qauv ntawm qhov sib txawv.

Cov cim cuab yeej –builds cov cim kev cai thiab cov ntawv sib txawv ntawm cov ntawv hlau, zoo rau kev thov sib dua los yog thaum muaj qhov siab ntawm kev txhim kho-kev txhim kho. Txhua yam khoom siv kho vajtse thiab cov ntsuas hluav taws xob uas xav tau tuaj yeem tsim kho kom tiav hauv.

Peev Xwm

|

Cov Txheej Txheem |

Laser txiav, Ntshav txiav, Waterjet txiav, CNC punching, CNC dabtsi yog khoov, vuam, sib dhos, thiab lwm yam |

|

Cov Khoom Siv |

Txhuas, Hlau, Stainless hlau, tooj dag, tooj liab |

|

Tiav |

Anodized, sandblasted, polished, hmoov coated, electroplated, thiab lwm yam |

|

Kev Soj Ntsuam |

Kev Thib 1 Kev Tshuaj Ntsuam Xyuas, Hauv Txheej Txheem, Kawg |

|

Kev lag luam siab |

Kev ua liaj ua teb, Tsheb, tsheb, khoom siv hluav taws xob, kev kho mob, rooj tog zaum, kho vajtse, tshuab, thiab lwm yam |

|

Cov kev pabcuam ntxiv |

CNC Machining, CNC Raws, Hlau Stamping, Ntawv Hlau, Tiav, thiab lwm yam |